YouTuber’s homemade electric motor from LEGO bricks spins at 4,000 rpm

In a world filled with high-tech robotics kits and programmable gadgets, one artist decided to strip everything back to the fundamentals of physics. Jamie from the YouTube channel Jamie's Brick Jams built a fully working electric motor using mostly ordinary LEGO bricks[1], a handful of basic electronic parts, and simple electromagnetic principles. No advanced motor modules.

No complex control boards. Just magnets, copper wire, a transistor, and a 9-volt battery. "Most motors need a controller, but not this one.

It has no microcontroller, no speed controller, and no mechanical commutator," Jamie said[2] in his video. The result is one of the simplest motors the world has ever seen. Through this project, Jamie shows that the core ideas behind modern machines--cars, fans, and even industrial robots--can be understood with simple components and a bit of patience.

Magnets, motion, and a spinning heart

Electric motors usually look complicated because they hide their essential parts inside metal[3] casings.

However, at their heart, they rely on a simple principle: when electricity flows through a coil of wire, it creates a magnetic field. If that magnetic field interacts with a permanent magnet, motion happens. Jamie's motor begins with a rotor--the spinning part.

The rotor uses two neodymium magnets mounted opposite each other across an axle. They are carefully balanced so that the rotor spins smoothly without wobbling. Keeping the magnets steady during testing required a small amount of temporary glue.

"I used a couple of these strong 20x 10 mm neodymium magnets. You can use more than two, but these two should give us a good speed on the rotor," Jamie added. Next to the rotor sits the driving coil.

Jamie hand-wound about 150 turns[4] of 27-gauge copper wire around a LEGO form[5]. When electricity flows through this coil, it produces a magnetic field. That magnetic field pushes or pulls on the rotor magnets, giving them a small push.

The motor starts with a single pulse from a 9-volt battery. However, one pulse alone only keeps it spinning for a few seconds. Momentum quickly fades.

This is the main challenge with simple motors: they need precise timing. If the magnetic push happens at the wrong moment, the rotor can slow down or stop.

The pulse that keeps it alive

To maintain continuous motion, Jamie added a second coil that acts as a sensor. This sensor coil has about 100 turns of thinner 32-gauge wire.

When one of the rotor magnets passes by, it induces a tiny current in the sensor coil. That small signal is sent into a simple circuit containing a single TIP31C transistor and an optional LED indicator.

[embedded content]

The transistor acts like an automatic switch. When it detects the signal from the sensor coil, it briefly turns on and sends a short burst of power from the battery to the driving coil.

This burst gives the rotor another perfectly timed push. Each pulse also makes the LED blink[6], showing that the timing is correct. This continuous cycle--detect, pulse, nudge--keeps the rotor spinning.

However, "it is worth noting that the polarity of the sensor and the driver coil does matter," Jamie said. For instance, if the connections to one of the coils are reversed, the motor may not spin properly. Swapping the wires usually fixes the problem.

Even though the transistor carries more current than its ideal rating, it remains stable and reliable in this setup. The electronics are minimal: one transistor, one LED, two coils, and a battery. In its simplest two-magnet form, the motor reaches about 1,300 revolutions per minute (RPM) before gearing.

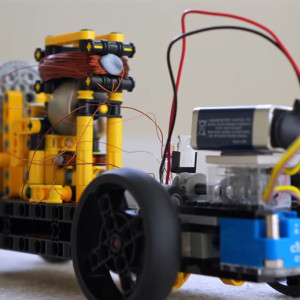

When Jamie adds a 3:1 gear reduction, the speed drops, but the torque increases significantly. With extra LEGO gears[7], a belt drive, and even an old steering system from a 1990s LEGO set, the motor can power a small LEGO car across a surface.

The LEGO motor mounted on a toy car. Source: Jamie's Brick Jams/YouTube[8]

The LEGO motor mounted on a toy car. Source: Jamie's Brick Jams/YouTube[8]

Jamie later experimented with an upgraded rotor using eight magnets arranged on a disc.

The same coils were used, but performance changed. The speed dropped to around 480 RPM. However, torque increased greatly, and the motion became smoother.

This is because the magnets pass the sensor more frequently, the pulses come faster, and are more evenly spaced. This steadier force allows the small vehicle to move with much greater confidence. "I've got to say, I just love that this thing is working all through its own self-timing," Jamie said.

Looking at a motor from the inside

At first glance, this may look like a simple hobby project.

However, its importance lies in clarity. Electric motors[9] power much of the modern world--from household appliances to electric vehicles. Yet many people never see how they truly function. By building a motor from visible, understandable parts, Jamie makes electromagnetism tangible.

Through his work, students and learners can see timing, magnetic interaction, and feedback control happening in real time.

Recommended Articles

References

- ^ ordinary LEGO bricks (interestingengineering.com)

- ^ said (youtu.be)

- ^ essential parts inside metal (interestingengineering.com)

- ^ 150 turns (www.techeblog.com)

- ^ a LEGO form (interestingengineering.com)

- ^ makes the LED blink (interestingengineering.com)

- ^ LEGO gears (interestingengineering.com)

- ^ Jamie's Brick Jams/YouTube (youtu.be)

- ^ Electric motors (www.eti.kit.edu)