Tying Up Loose Ends On A Rope-based Robot Actuator

One of the perennial challenges of building robots is minimizing the size and weight of drive systems while preserving power. One established way to do this, at least on robots with joints, is to fit each joint with a quasi-direct-drive motor integrating a brushless motor and gearbox in one device. [The 5439 Workshop] wanted to take this approach with his own robot project, but since commercial drives were beyond his budget, he designed his own[1] powerful, printable actuator. The motor reducing mechanism was the biggest challenge: most quasi-direct drives use a planetary gearbox, but this would have been difficult to 3D-print without either serious backlash or limited torque.

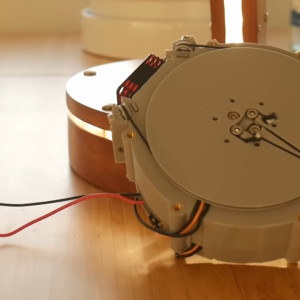

A cycloidal drive was an option, but previous printable cycloidal drives seemed to have low efficiency, and they didn't want to work with a strain-wave gearing. Instead, he decided to use a rope drive (this seems to be another name for a kind of Capstan drive[2]), which doesn't require particularly strong materials or high precision. These normally use a rope wound around two side-by-side drums, which are difficult to integrate into a compact actuator, but he solved the issue by putting the drums in-line with the motor, with two pairs of pulleys guiding the rope between them in a "C" shaped path.

To build the actual motor, they used a hand-wound stator inside a 3D-printed rotor with magnets epoxied into it, and used Dyneema rope in the reducer for its high strength. The printed rotor proved problematic when the attraction between the rotor and magnets caused it to flex and scrape against the housing, and it eventually had to be reinforced with some thin metal sheets. After fixing this, it reached five Newton-meters of torque at one amp and nine Newton-meters at five amps.

The diminishing returns seem to be because the 3D-printed pulley wheels broke under higher torque, which should be easy to fix in the future. This looks like a promising design, but if you don't need the output shaft inline with the motors, it's probably easier to build a simple Capstan drive, the mathematics of which[3] we've covered before. Both makers we've previously seen build Capstan drives used them to make robot dogs[4], which says something for their speed and responsiveness[5].

[embedded content]

References

- ^ designed his own (www.youtube.com)

- ^ Capstan drive (hackaday.com)

- ^ mathematics of which (hackaday.com)

- ^ make robot dogs (hackaday.com)

- ^ speed and responsiveness (hackaday.com)