Motor efficiency: a must-have for 2026

According to the International Energy Agency (IEA)'s World Energy Outlook 2025[1], global energy demand grew by more than 2% in 2024 to over 650 exajoules (EJ): well above the long-term average of 1.4% growth [2.2.1]. ABB's standpoint is clear. Improving industrial energy efficiency -- straightforwardly reducing the amount of energy that capital machinery needs to achieve the same level of production -- should be a core strategy in the fight against this staggering level of energy use.

Yet efficiency gains are slowing, not accelerating. That is an urgent call to act where the potential is largest and most accessible. For industry, that place is the electric motor.

A huge untapped opportunity

Electric motors are the workhorses of the industrial world.

They power pumps, fans, compressors, conveyors, mixers in every sector from food and beverage to mining and water treatment. They account for the majority of industrial electricity use. But the IEA's report highlights that only three fifths of industrial electric motors are covered by minimum energy performance standards (MEPS) [1.10.1].

In other words, a vast share of the global installed motor base, which we estimate is around 300 million, still operates below today's best available efficiency levels, and often without any form of speed control. The consequences are material. The report finds that stronger action on efficient motors, drives and other efficiency policies in industry could avoid about 5 EJ of industrial energy demand by 2035 [4.3.3].

Five exajoules, for reference, is comparable to the amount of electricity generated by the entire Middle East in 2024: 1,461 TWh, or 5.26 EJ [Table A.16]. If we are serious about using energy more wisely, closing this motor efficiency gap is one of the most obvious next steps that industrial sectors can take.

The logical first move

One of the most encouraging findings in the World Energy Outlook is that the tools we need already exist and make economic sense. The IEA notes that many efficiency measures (including high efficiency motors) are cost-effective and have short payback periods, helping lower operating costs for industry [7.3.2].

When 97% of a motor's lifetime cost typically comes from the energy it consumes, not from the purchase price or maintenance, efficiency quickly becomes the defining factor for total cost of ownership. This is why at ABB we started pioneering Synchronous Reluctance Motor[2] (SynRM) technology as early as 2011. SynRM delivers high efficiency and performance without permanent magnets or rare earth metals, and our portfolio today includes IE5 "Ultra-Premium" and even the anticipated IE6 "Hyper-Efficiency" models in selected ratings.

We now offer SynRM from 0.75 kW up to 450 kW, enabling high efficiency in both small and large applications. In practical terms, upgrading from a standard IE3 motor to an IE5 SynRM ultra-premium efficiency motor paired with a variable speed drive (VSD), can reduce motor energy losses by up to 40% in many applications. In a pump or fan, this can translate into thousands of euros in savings each year and large CO2 reductions over the motor's lifetime.

For example, in a 110 kW, 1500 rpm pump running continuously at 75% power, that could mean reductions of EUR4,897 in energy costs and 5,677 kg of CO2 emissions a year. That's EUR97,940 and 113,540 kg of CO2 saved over a single motor's 20-year lifespan. Scaled across dozens, hundreds, or thousands of motors in a single plant, the potential impact is astounding.

The point is that high-efficiency motors exist today, they are technically mature, and payback times are often measured in months, not years. Such a combination of "proven", "available", and "fast payback" is rare in the energy transition. Industry should be scrambling to seize it.

Scaling impact with digitalization and electrification

The IEA also underlines how two other trends amplify the role of efficient motors: electrification and digitalization.

As more processes switch from fossil fuels to electricity -- for example, with electric heating, heat pumps, or compressors -- the share of industrial energy running through motors and drives will only grow. By 2035, the report says, that could be 50% higher than today [4.3.3]. The problem is that if we electrify systems that are currently inefficient, we lock in higher demand and higher costs for decades.

However, if we electrify using the most efficient motors and drives available, we offset much of that demand growth and make decarbonization easier. Digitalization is the second multiplier. The IEA notes that AI and digital optimization can further boost efficiency by 3-10% across transport and industry, equivalent to a total energy saving slightly larger than the full demand of Indonesia today (around 13.5 EJ) [1.5.3].

For motor-driven systems, that means using connected drives, sensors and analytics to:

- Size equipment correctly and avoid overspecification

- Match motor speed to actual process needs in real time

- Predict and prevent failures that cause inefficient operation

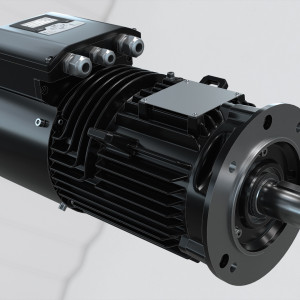

Integrated solutions like ABB's LV Titanium variable speed motor[3] platform go in this direction: combining an IE5 Ultra-premium efficiency plug-and-playmotor with a purpose-designed drive in a single compact package. It arrives factory-configured and can be installed without complex redesigns or separate drive cabinets. That kind of simplicity makes it easier to turn digital optimization and variable-speed control into standard practice rather than the exception.

The broader lesson is this: efficiency from better hardware and efficiency from smarter control must go hand in hand. We have seen this approach working in practice. For example, when a major copper producer replaced older induction motors[4] with high-efficiency IE4 and IE5 motors paired with modern drives, the result was annual savings of 25 GWh and a reduction of around 12,000 tonnes of CO2, with a payback of just a few years.

Turn every motor into a climate solution

Electrification of industrial processes will continue, and electricity demand will rise; but how much it rises is still in our hands.

ABB's take is that upgrading the world's motor systems is one of the most direct, least risky, and most cost-effective levers industry has. The priorities are clear. Extend and tighten motor efficiency standards, and support retrofit programs.

Treat premium motor and drive upgrades as a strategic investment, not as optional CapEx. And continue to innovate in motor design, integration and digitalization -- while making upgrades simple, compatible with legacy systems, and fast to implement. The technology already exists, but for us, being Engineered to Outrun goes further.

It's a mindset of continuous evolution, creating systems designed to excel today and keep delivering efficiency and sustainability well into the future.

The last Industrial Revolution was all about producing more than ever before.

The next will be about how we use less than ever to do it.

References

- ^ World Energy Outlook 2025 (www.iea.org)

- ^ Synchronous Reluctance Motor (www.abb.com)

- ^ ABB's LV Titanium variable speed motor (www.abb.com)

- ^ when a major copper producer replaced older induction motors (new.abb.com)