GE Aerospace tests new hybrid electric engine for future aircraft

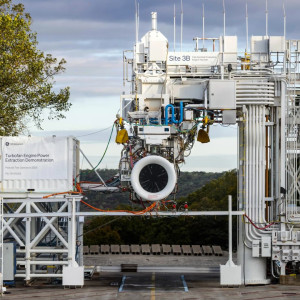

GE Aerospace announced on January 26 that it reached a key milestone in hybrid-electric aviation, confirming a successful ground test of a commercial turbofan engine that can extract, transfer, and reinsert electrical power while running. The test was completed in 2025 at the company's Peebles Test Operation in Ohio, marking a first-of-its-kind integrated demonstration carried out under NASA's Turbofan Engine Power Extraction Demonstration project. The achievement goes beyond testing individual parts.

It showed a full hybrid electric engine system operating together in real conditions, generating data that could shape the next generation of single-aisle aircraft used across the United States.

Hybrid turbofan proves integrated power flow

The demonstration used a modified Passport high-bypass turbofan engine. Engineers configured the engine so it could pull electrical energy from certain operating stages and inject that power into other sections when needed. This approach allows the engine to supplement thrust electrically during different phases of flight, without relying on onboard batteries.

GE Aerospace is developing this narrowbody hybrid electric architecture to improve efficiency while keeping flexibility. The system can operate with energy storage if available, but it does not depend on batteries to function. That design choice reduces weight and complexity, two major challenges for electric aviation.

"Hybrid electric propulsion is central to how GE Aerospace is redefining the future of flight," stated[1] Arjan Hegeman, vice president of future of flight for the company. "Our latest milestone successfully demonstrated a narrowbody hybrid electric engine architecture that doesn't require energy storage to operate. It's a critical step to making hybrid electric flight a reality for commercial aviation with technologies that meet customer needs for greater efficiency, durability, and range."

According to NASA, the test exceeded technical performance benchmarks. These benchmarks were defined using industry input to ensure the technology could deliver meaningful fuel cost savings for U.S. airlines while still meeting future aircraft power demands.

NASA collaboration delivers real engine data

For NASA researchers, the test represented something they had not seen before. Previous work focused on separate elements such as electric motors, power electronics, and control systems.

This was the first time those elements were brought together inside a working turbofan engine[2]. "Turbines already exist. Compressors already exist.

But there is no hybrid-electric engine flying today. And that's what we were able to see," highlighted Anthony Nerone, who served as manager of the agency's Hybrid Thermally Efficient Core project at NASA's Glenn Research Center in Cleveland during the engine's development. The work falls under NASA's HyTEC cost-sharing contract with GE Aerospace.

The hybrid engine still burns jet fuel, but electric motors assist key operations. While the concept may sound familiar from hybrid cars, scaling it to an engine capable of powering a single-aisle airliner required new designs, new integration methods, and extensive safety validation. "They had to integrate equipment they've never needed for previous tests like this," said[3] Laura Evans, acting HyTEC project manager at Glenn.

RISE program pushes electric engine concepts

The power extraction test also supports the broader CFM International RISE program, which GE Aerospace is advancing to mature technologies for more electric aircraft engines[4].

Launched in 2021, the program has already completed more than 350 tests and over 3,000 endurance cycles. RISE research covers multiple engine concepts, including Open Fan designs, compact cores, and hybrid electric systems. The program targets more than 20 percent lower fuel burn compared to today's in-service commercial engines, with a strong focus on durability and safety.

CFM expects RISE technologies to move toward ground and flight testing later this decade, with ongoing work on aircraft and engine integration alongside industry partners.

Decades of work point toward future aircraft

GE Aerospace's hybrid electric experience stretches back nearly ten years. Milestones include a 2016 ground test of an electric motor-driven propeller and a 2022 demonstration of a megawatt-class, multi-kilovolt hybrid propulsion system tested at simulated altitudes up to 45,000 feet. In 2025, GE Aerospace also announced a strategic partnership and equity investment with BETA Technologies to develop a hybrid electric turbogenerator for advanced air mobility aircraft.

For NASA, the progress reflects a long-term effort that began roughly 20 years ago. "When you go to a conference, hybrid technology is everywhere," Nerone said.

Recommended Articles

References

- ^ stated (www.geaerospace.com)

- ^ turbofan engine (interestingengineering.com)

- ^ said (www.nasa.gov)

- ^ aircraft engines (interestingengineering.com)