System-level impact of electrification on road freight transport efficiency

System Dynamics (SD), rooted in control theory and systems thinking45, is a method for understanding complex systems with many interacting variables and feedback loops17. As detailed in the section "Literature overview", the road freight transport system is one such complex system.

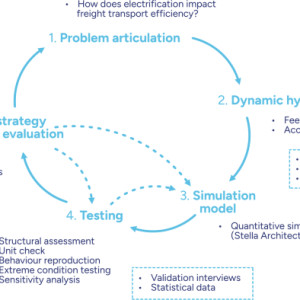

Moreover, it involves multiple stakeholders such as shippers, carriers, infrastructure providers, and the public sector32, making the SD methodology particularly relevant to our study. To develop the SD model for this study, we followed the standard SD methodological process17, as shown in Fig. 1 and explained in the text. In total, we engaged 35 experts from public authorities, industry, and academia, as detailed in Supplementary Information 2.

Fig.1: Methodological process of the study.

A mixed approach of literature review, semi-structured interviews, a group model building workshop, and validation interviews. The figure is based on the standard SD methodological process17.

Full size image[1]The problem and its boundaries were defined through a literature review (see Supplementary Information 3 for an overview). To further refine the problem and develop the dynamic hypothesis, we conducted eight semi-structured interviews with experts from public authorities, industry, and academia, following the method outlined by Luna-Reyes and Andersen46.

During the semi-structured interviews, we guided discussions with experts using a predefined set of questions that covered various variables and dynamics (see Supplementary Information 2). In the next step, a Group Model Building workshop was conducted, involving eleven experts from the public authorities, industry, and academia. Group Model Building is a participatory approach in SD, where stakeholders collaborate to create a dynamic model of a complex system to understand the underlying causes and feedback structures that drive system behaviour47,48,49. During the workshop, participants were involved in three main activities: eliciting key variables, initiating a causal loop diagram, and understanding the impacts of different policies (see Supplementary Information 2 for descriptions of the activities).

Causal Loop Diagrams (CLDs) from different groups in the workshop were the main outcomes. Building on the insights from the literature, interviews, and workshop, we developed a refined Causal Loop Diagram (CLD) and a simulation model utilising Stella Architect version 3.2.1. These were iterated with the experts through various meetings aimed at evaluating the model's structure, the accuracy of the mathematical equations, and the quality of the exogenous data.

Data collection was supported by relevant official authorities and experts in the field. To validate the model, we conducted a series of tests, including structural assessment, unit checks, behaviour reproduction, extreme condition tests, and sensitivity analysis, based on Sterman17.

Additionally, we conducted five interviews with experts to confirm the validity of the model (based on Richardson & Pugh50). Furthermore, based on the sensitivity analysis and collaborative meetings with experts, various policy levers were developed.

These were subsequently evaluated through policy and scenario analyses to assess the impact of different policies on the system.

Model structure: dynamic hypothesis

Figure 2 illustrates the dynamic hypothesis in the form of a Causal Loop Diagram (CLD) and shows the key feedback loops underlying the problem.

Fig.2: The simplified causal loop diagram (CLD).

The positive signs on the arrows indicate influence in the same direction; the negative signs on the arrows indicate influence in the opposite direction. The loops are indicated in the legend on the right, and each loop is identified as either a reinforcing (R) or a balancing (B). Supplementary Information 4 provides details on the loops and dynamics of various variables.

Full size image[2]The feedback loops in Fig. 2 show that as freight demand (in ton) rises, the demand for trucks increases.

Therefore, the supply side reacts by buying new trucks, either diesel or E-trucks. As a result, the total number of trucks rises, increasing the transport cost. The transport cost increases in turn the cost per ton, bringing a decrease in demand.

The loops of transport cost (B1 & B2) limit the demand growth. In contrast, the economy of scale (R1) reinforcing loop illustrates how the growth in freight demand (in ton) reduces transport cost per ton. Lower costs trigger an increase in induced demand due to price changes.

Therefore, the higher the freight demand, the lower the cost per ton, further boosting the freight demand (see refs. 51,52). The interplay between the three loops - R1, B1 & B2 - determines if the freight demand increases, decreases, or is in equilibrium. Furthermore, the transport efficiency is related to this interplay, as it is measured as the freight demand divided by the capacity of the supply.

The right side of Fig. 2 depicts the dynamics of the four factors influencing the attractiveness and market share of E-truck sales: the cost savings by using E-trucks, the availability of charging infrastructure, the technology maturity of E-trucks, and the emission ratio compared to the baseline. The cost savings by using E-trucks increase with an increase in technology maturity and positively influence the E-truck sales share. The technology maturity is influenced by the number of E-trucks sold.

Therefore, the higher the number of E-trucks, the higher the technology maturity53. This has a dual effect, increasing directly and indirectly (through the cost savings) the E-truck sales share. These two effects are depicted by the loops Tech maturity (R2) and Cost saving (R3).

Moreover, as more E-trucks enter the market, the demand for charging stations increases54.

In the E-trucks use charging (B3) balancing loop, this increased demand for charging stations results in a reduced availability of charging stations, hindering E-truck sales. However, in the E-truck increase charging (R4) reinforcing loop, the surge in demand for charging stations motivates the construction of more stations, consequently increasing availability. This positive feedback loop, in turn, boosts E-truck sales.

Finally, the E-truck sales share reduces the number of diesel trucks in the fleet. This reduction in turn reduces the emission ratio compared to the baseline, which boosts E-truck sales share55. This dynamic is represented in the reinforcing loop E-truck decrease emission (R5).

Main model assumptions

The main model assumptions are as follows. The definitions of different kinds of efficiencies are based on the literature and the expert opinions.

It is important to consider how we define and calculate efficiency when the results are used (see the section "Model Structure: simulation model" for a detailed definition of the efficiency variables). Four factors are considered as E-truck adoption drivers: cost saving, availability of charging infrastructure, technology maturity, and emission ratio compared to the baseline. In addition, we assume that cost savings influence E-truck adoption once cost parity is achieved.

Prior to that, adoption is driven by infrastructure availability, technology maturity, and emission ratio compared to the baseline. The model is based on the Swedish market and government. The structures have been validated with experts and policymakers based in Sweden.

Only E-trucks and diesel trucks are considered in the model. Hybrid, hydrogen-fuelled, biofuel, and other alternative fuel trucks are not included. This focus was informed by our expert group during the problem articulation phase, where they identified E-trucks as having the greatest potential for emission reduction in the sector, an insight supported by recent literature (e.g., refs. 5,56). The category of trucks studied includes heavy trucks, defined in Sweden as those weighing over 3.5 tonnes. Additionally, there are no separate classifications within this category; all trucks over 3.5 tonnes are considered as a single group.

This assumption is based on the fact that most Swedish data sources, such as Trafikanalys, SCB, and Trafikverket, aggregate all trucks over 3.5 tonnes into a single category, with limited or inconsistent disaggregation data. Aggregating these subclasses also reduces the complexity of the model and aligns with the system-level scope of the study. The simulation time spans from 2010 to 2050.

Starting from 2010 allows for validation against historical data (2010-2023) and aligns with the base year used in Sweden's climate goal4. Extending the model to 2050 provides a reasonable future outlook to ensure sound policy analysis, in line with our expert opinion.

Equal lifetimes of trucks are assumed for E-trucks and diesel trucks57, as definitive values for these parameters for E-trucks have not yet been established. However, this parameter, along with others, is adjustable in the model and online interface, enabling users to explore how varying assumptions influence the simulation results.

Different types of stationary charging, including depot, highway, and destination charging, are aggregated in the model. The focus is on the overall impact of charging station availability on E-truck adoption, rather than on the dynamics or competition among specific charging options. In addition, other charging strategies, such as Electric Road Systems (ERS) and battery swapping, are excluded, in line with the focus of EU-level planning initiatives such as the Alternative Fuels Infrastructure Regulation (AFIR) and Sweden's national plan58. Freight demand is calculated by considering the growth in population and a fixed demand rate of each person in one year. Moreover, an elasticity of -151 is considered to model the variation of demand due to the variation in price.

Model structure: simulation model

The simulation model comprises 268 variables, 165 equations, and 16 stocks, organised into 9 sectors that are described in detail in the following texts. A simple representation of the simulation model is presented in Fig. 3.

The Stella Architect version is available in Supplementary Information 5, and full model documentation is provided in Supplementary Information 6. In addition, because efficiency variables are central to this research, a table in Supplementary Information 6 summarises all efficiency variables modelled in the study, along with their definitions, calculation formulas in the SD model, and the impact of electrification.

Fig.3: Simplified stock and flow diagram.

The diagram illustrates nine sectors, with some represented together for simplification. Many variables and arrows are excluded to enhance clarity.

Full size image[3]Freight demand sector is described as follows.

The main goal of this sector is to calculate the freight demand in ton km for road transport. This is calculated by multiplying the demand rate, the Population of Sweden and the AVERAGE DISTANCE WEIGHTED BY TON. Note that parameters are written in capital letters throughout this section.

-

The demand rate considers a base demand rate taken from transport statistics59, and it is influenced by the Effect of Price Change on Demand Rate. This effect is calculated as a stock that takes into account the fractional change in price per ton per year and the elasticity between cost and demand. In practice, this structure gives an increase in demand when prices drop and vice versa.

The elasticity is assumed to be constant and equal to -151.

-

The Population of Sweden is calculated as a stock to match the population statistics and projections60.

-

The AVERAGE DISTANCE WEIGHTED BY TON variable represents the average distance that each ton travels (from a demand side) in the system.

This is not related to any operational value, but rather it measures the average distance between origin and destination. The data is taken from the Samgods PWC matrix59, which states all the origins and destinations of trips in the freight transport system of Sweden.

Efficiency of supply sector is described as follows.

The goals of this sector are twofold: to calculate the demand for vehicles and to calculate the transport efficiency. The demand for vehicles is calculated considering the needed freight supply to satisfy the demand, which is calculated by multiplying the demand by the RATIO BETWEEN SUPPLY AND DEMAND. This ratio represents how much transport work from the supply side is needed to satisfy the demand.

This ratio is calculated using data from the Samgods PWC matrix59 and Trafikanalys61.

Moreover, when electrification begins, the total detour in ton km is also added to the needed supply. This depends on the detour distance per E-truck, which is influenced by the availability of charging infrastructure, calculated within the charging infrastructure sector. The transport efficiency is calculated considering the freight demand in ton km and the maximum possible transport work.

This maximum work is the total transport work that would be possible if all trucks were to operate at maximum capacity (always full) and drive the maximum annual mileage. The transport efficiency can be seen as the combination of three other kinds of efficiencies, described below. A summary of all efficiency variables modelled in the study is provided in Supplementary Information 6.

-

The routing efficiency, which considers the ratio of the freight demand in ton km and the transport work.

The number of trucks and the actual transport work per truck are used to calculate the transport work. Routing efficiency is decreased by the need for E-trucks to take more detours during the early stages of adoption when charging infrastructure is limited. As adoption progresses and charging infrastructure expands, routing efficiency improves, approaching pre-electrification levels.

-

The fill rate, which considers the ratio of transport work and the potential transport work considering a full load, where potential transport work is the amount that could be carried out if all trucks were always travelling full.

Fill rate decreases in the early stages of E-truck adoption due to the battery weight of E-trucks. As adoption progresses and battery technology matures, battery weight decreases and fill rate improves.

-

The vehicle utilisation, which considers the ratio of the potential transport work considering a full load and the maximum possible transport work. Vehicle utilisation decreases due to a reduction in total available driving time, as there is some time required during shifts for E-truck detouring, queuing and charging.

As more charging infrastructure is built, detouring and queuing time decreases, improving vehicle utilisation. However, vehicle utilisation remains lower than pre-electrification levels due to the charging time required during the shift.

The fleet sector is described as follows. In the fleet sector, the demand for trucks and the E-truck sales share (explained in the next sector) are used to calculate the diesel truck sales and the E-truck sales.

These sales are inflows to the Diesel Truck Fleet and E-truck Fleet stocks. In turn, these stocks have truck decommissioning as outflows. The total number of trucks is calculated as the sum of the two fleets.

The E-truck Sales sector is described as follows. The E-truck sales share is determined considering four factors: cost savings by using E-trucks, availability of charging infrastructure, E-truck technology maturity, and emission ratio compared to the baseline. Each factor varies from 0 to 1, with 0 corresponding to zero influence and 1 corresponding to maximum influence.

Each factor has a different weight, and an innovator rate of 2.5%62 is considered as the base growth rate to start the adoption. In this way, when all four factors reach their maximum, the result is an E-truck sales share of 100%.

-

The cost savings by using E-trucks are considered in terms of the ratio between the annual cost of one E-truck and one diesel truck.

The cost savings are maximum when this ratio reaches the minimum value. Cost-related considerations consistently emerge as a dominant factor in adoption decisions (e.g., refs. 57,63,64).

-

The availability of charging infrastructure considers the ratio between the number of charging stations and the demand for charging stations by E-trucks. The influence of this availability on E-truck sales is maximum when the availability is 1. Availability of charging infrastructure is also recognised as an important enabler (e.g., refs. 19,54,65).

-

The technology maturity considers the ratio of technology maturity to the goal. This ratio measures the progress of technology maturity compared to the set goal.

The influence of maturity is maximum when the ratio is 1. Prior works (e.g., refs. 66,67) point to the significance of vehicle and battery technology maturity.

-

The emission ratio compared to the baseline considers the emission reduction ratio compared to the emissions during 2010. The influence of the emission is maximum when the emission ratio compared to the baseline is lowest. As E-trucks produce no tailpipe emissions, environmental performance is another motivator for adoption (see e.g., refs. 55,68).

The cost sector is described as follows. In the cost sector, the annual cost of one diesel truck and of one E-truck is calculated, considering the cost of diesel fuel (or of electricity), the maintenance cost, and the annual purchase cost63,69. The E-truck purchase cost is calculated in the technology maturity sector and decreases over time. Moreover, the annual employee cost for each vehicle is calculated.

These costs allow us to understand the cost parity point between E-trucks and diesel trucks. Moreover, the annual total cost is calculated considering the entire fleet, and the cost per ton is calculated by dividing the annual total cost by the freight demand in ton. The cost per ton is used in the freight demand sector to understand the rebound effect of a change in cost on the demand for freight transport.

Note that a discount rate was not applied when calculating the costs. The emissions sector is described as follows. In the emissions sector, the total annual emissions are calculated as the annual emissions from diesel trucks, considering the distance driven by the diesel truck fleet.

The total annual emissions are then compared with the emission level in 201070, resulting in the emission ratio compared to the baseline, which is considered as one kind of efficiency.

The reason for this comparison is that Sweden's transport climate target is to reduce emissions by a minimum of 70% by 2030 compared to the levels of 20104. The emissions coming from the production of electricity are omitted, as in Sweden's transport climate target only operational emissions (tank-to-wheel) are considered.

Similarly, the emissions from diesel trucks are calculated considering the carbon intensity of diesel fuel, corresponding to the equivalent carbon dioxide emissions per litre of diesel consumed during driving (tank-to-wheel). Naumov et al.71 used a similar approach to model emissions. The Truck Characteristics sector is described as follows.

In this sector, the characteristics of diesel and E-trucks are calculated separately to be used in the other sectors. The main outputs of this sector are the fleet average load, truck capacity, total distance, and transport work. Each of these variables is a weighted average considering the share of diesel and E-trucks.

The load is calculated, including both loaded and empty km. The E-truck capacity is calculated excluding the weight of the battery. The total distance and transport work of the E-trucks are calculated, including the potential detours to charging stations and considering the potential extra time needed for charging.

The Charging Infrastructure sector is described as follows. The infrastructure is planned by considering the current E-truck Fleet and calculating the current demand for charging stations based on the average station demand per E-truck. The Installed Charging Stations is a stock that has an inflow of building stations and an outflow of scrapping stations.

The TIME TO PLAN AND BUILD A STATION is considered a delay in the system together with the LIFETIME OF A CHARGING STATION72,73. The average station demand per E-truck is calculated using three variables:

-

The kWh consumption of one E-truck is calculated by multiplying the annual total distance per E-truck by its energy consumption per kilometre.

-

The Average Power of Charging Station is assumed to increase over time due to technological advancements74.

-

The possible utilisation rate of a station changes over time, bounded between two values.

The lower bound reflects the limited and uneven distribution of charging stations during the early phase of E-truck adoption, while the upper bound represents the maximum achievable technical level. As adoption progresses, the utilisation rate gradually transitions from the lower to the upper bound, following the growth in the share of E-trucks.

Two efficiencies related to the charging infrastructure are defined in this sector:

-

The availability of charging stations is calculated by dividing the Installed Charging Stations by the current demand for charging stations.

-

The utilisation rate of charging stations is calculated by dividing the kWh consumption by the E-truck fleet (total annual energy consumption by the E-truck fleet) and the kWh capacity of all installed stations (combined energy capacity of all installed charging stations over a year).

Based on the availability of charging stations, a queuing time and a detour time are calculated. If the availability is 1, both the queuing and detour times are zero.

If the availability is zero, both queuing and detour time are at their maximum value. These variables influence the E-truck characteristics and therefore the efficiency of the system as a whole. The E-truck Technology Maturity Sector is described as follows.

The E-truck Technology Maturity is calculated as a stock, with inflow learning in E-truck technology, inspired by Nieuwenhuijsen et al.53. The learning is done thanks to R&D spending and based on the TECHNOLOGY IMPROVEMENT PER SEK SPENT. So for each SEK spent in R&D, the technology maturity accumulates.

The R&D investment comes from the private sector, and especially from the income from diesel and E-truck sales. The technology maturity influences three variables, which in turn influence the cost and characteristics of E-trucks:

-

The E-truck purchase cost, which decreases the closer the technology reaches its maturity. The minimum E-truck purchase cost is set as equal to the DIESEL TRUCK PURCHASE COST63.

-

The Battery Weight (ton/kWh), which decreases the closer the technology reaches its maturity. Both initial and minimum battery weights are taken from Zu & Li75 and re-evaluated with updated data from Teichert et al.76.

-

The Average Power of Charging Station, which increases the closer the technology reaches its maturity. Both initial and maximum power are taken from ACEA74.

Model validation

To ensure the accuracy and reliability of the simulation model, various validation tests were conducted using the methods proposed by Sterman17. A structural assessment validation process was conducted through meetings with experts, as mentioned in the methodological process. Moreover, the model passed the unit check function, confirming that the dimensional consistency is respected.

Eight extreme condition tests were carried out, involving setting selected model parameters to extreme values and comparing the behaviour generated by the model with the expected behaviour, which is available in Supplementary Information 7. In addition, several behaviour reproduction tests were conducted to validate the model against real-world trends. However, behaviour validity is less critical than in classical forecasting models, as the model represents a future system with limited calibration data.

A point-by-point match with observed behaviour is neither feasible nor essential. The main results of these tests are presented in Supplementary Information 8. Finally, 26 sensitivity analyses have been conducted to examine the model's responsiveness to changes in parameters for which data was unavailable or limited.

Some of these are further explored in the section "Sensitivity analysis"; the rest is reported in Supplementary Information 9. From the sensitivity results, a selection of policies was run. Supplementary Information 10 reports information on all the policies, while the results of the most influential policies are presented in the section "Policy analysis".

All input parameters are obtained from official statistics and relevant scientific research.

For transparency and reproducibility, all input data utilised in the model is provided in the model documentation, which can be found in Supplementary Information 6, including detailed references or sources for each input parameter.

References

- ^ Full size image (www.nature.com)

- ^ Full size image (www.nature.com)

- ^ Full size image (www.nature.com)