Modular axial flux motor-generator with plastic stator and tunable gearset launched as PMSM alternative

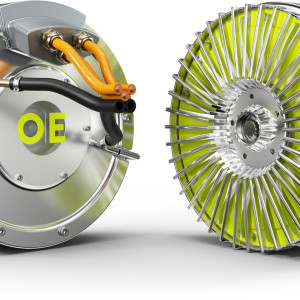

Orbis Electric[1] has introduced HaloDrive, an advanced axial flux motor-generator designed around a modular four-part architecture featuring an injection-molded plastic stator and a tunable gearset. The axial flux motor-generator has been designed for commercial transportation, trucking fleets, stationary industrial power generation and passenger vehicles, as well as marine systems and aerospace platforms. The technology acts as an alternative to electric motors such as permanent magnet synchronous motors (PMSM).

HaloDrive has been piloted by leading passenger vehicle OEMs for in-wheel propulsion systems and in heavy-duty trucking fleets as diesel replacement generators. In these commercial applications, the electric motor has reportedly delivered significant cost savings, and in one case, has been improved fleet fuel efficiency by 61%. Installed on the driveshaft or an axle, the HaloDrive motor converts the truck's braking energy into cost-saving electricity to power mobile refrigeration without plugging into the grid.

Orbis Electric's HaloDrive has been engineered to fit within a wheel, reducing vehicle weight and improving range by 20%. The system can be installed in three hours. One of the emerging and practical opportunities is using electric motors as generators for electric transport refrigeration unit (eTRU) configuration in commercial trucks.

When compared to diesel-powered units, HaloDrive has delivered up to 100% reduction in diesel refrigeration fuel consumption and emissions, according to Orbis Electric. The company also says HaloDrive is 90% less expensive to operate. "Our vision with HaloDrive is to significantly advance how businesses transition to electrification by removing electric motor barriers such as deployment costs, material and manufacturability risks, and performance limitations," said Chance Claxton, co-founder and CEO of Orbis Electric. "With HaloDrive, we offer a high-performance axial flux motor that is not only highly efficient and powerful but also environmentally sustainable."

The axial flux motor-generator matches the torque of a V8 engine, delivering torque density of 100Nm/kg. Its architecture supports multiple drivetrain positions (P2, P3, P4, P5), and provides up to 35% lower drivetrain costs compared to radial flux motors. The solution also functions at 97% operational efficiency.

"Our approach with HaloDrive is and always has been about creating a motor that not only meets the immediate electrification needs across a range of industries, but is also compact and efficient enough to position businesses for future energy and sustainability standards," said Marcus Hays, co-founder and CTO of Orbis Electric. "This is something our engineering team of EV, aerospace, fabrication and environmental experts have spent years developing.

We can achieve exceptional performance while also mitigating risks tied to rare earth materials, ensuring consistent availability and pricing stability."

In related news, Yasa has achieved what it states is the highest power density ever recorded for an electric motor[2], across any sector or application

References

- ^ Orbis Electric (www.orbiselectric.com)

- ^ highest power density ever recorded for an electric motor (www.automotivepowertraintechnologyinternational.com)