Bosch presents 800 V electric drive for construction machinery

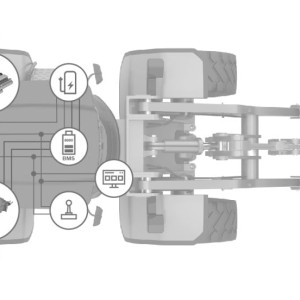

Bosch Engineering is bringing a new electric motor solution for construction machinery to the Bauma trade fair at the beginning of April. The unit, based on Bosch's SMG230 motor, is suitable for battery voltages of up to 800 volts and, according to Bosch, expands the range of applications for construction machinery. "The latest generation of our powerful electric drive system combines high power density, compact dimensions, and optimum efficiency," says Philipp Kurek, responsible for the Off-Highway and Marine division at Bosch Engineering. Even construction machinery with high power requirements and limited installation space, such as wheel loaders, can be equipped with an electric drive.

Let's get to the point: the motor is designed for system voltages of 400 to 850 volts and, according to Bosch, offers a continuous output of up to 200 kilowatts and a torque of around 250 Newton metres in the ideal voltage and temperature range.

Short-term torque of up to 550 Nm is even possible. According to Bosch, the power density has also been significantly increased thanks to the 800-volt technology. "Compared to a comparable 400-volt machine, the new motor delivers up to 80 kilowatts more power for the same weight or has more compact dimensions and significantly less weight for the same power," the manufacturer explains.

According to the company, the 800-volt inverter with silicon carbide semiconductors specially developed by Bosch as a supplement offers an "impressive efficiency of more than 99 per cent." The silicon carbide semiconductors in the power modules are known to enable faster-switching processes and steeper switching edges, as a result of which less energy is lost in the form of heat.

Bosch also emphasises the robustness and durability of the electric drive: "The safety and diagnostic concept is based on established standards from the automotive domain and has been adapted to the specific requirements of mobile machinery," says the company headquarters. The compact dimensions also enable easy integration into tight installation spaces, meaning that existing equipment platforms can also be converted to an environmentally friendly electric drive.

In this context, Bosch Engineering has pledged to support customers in collaboration with Bosch Rexroth (based on the open ECOsystem BODAS) in integrating the drive into construction machinery, including application development.

In principle, the engine specialist is convinced that the improved overall efficiency of the engine will lead to a lower TCO, meaning that electrification can also be financially worthwhile compared to diesel-hydraulic drives - depending on the application profile.

References

- ^ bosch-presse.de (www.bosch-presse.de)