Stellantis: production targets for combustion and electric motor plants in Europe

The Group Stellantis[1] commits to an ambitious energy transition in Europewith production targets for its internal combustion and electric motor plants. This rebalancing of production between combustion engines and electric motors meets the requirements of a market increasingly focused on electrification. After our dossier on Stellantis electric motors, Let's take a look at the plants and their production targets for internal combustion and electric motors in Europe.[2]

The Szentgotthard plant (Hungary): a pillar for internal combustion engines, and soon for electric motors

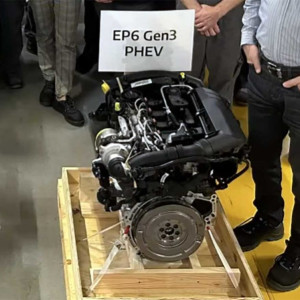

Among the group's most important plants, the Szentgotthard plant in Hungary, dedicated to the production of combustion engines, remains a major player in the production of combustion engines. This plant is responsible for the production of 1.2L and 1.6L engines, two engines widely used in Stellantis vehicles.

In a previous article, we mentioned that production target for the 1.6L PHEV engine[3] is 220,000 units per year. However, production targets for 1.2L engines, although already in circulation, have not been precisely specified for the coming years, nor have those for future electric motors. However, with production on the rise and the growing need for internal combustion engines for hybrid models, the target could be in the region of 1 million 1.2L engines per yearIn line with production targets for EDCT gearboxes developed by Punch Powertrain.

AdvertisingFrom 2026, this plant will also produce high-performance electric motors for Stellantis cars using the STLA Large platform.

Metz and Mirafiori: for the production of EDCT gearboxes

The Metz plant in France and the Mirafiori plant in Italy produce EDCT (dual clutch transmission) gearboxes, a key component in the production of the Stellantis Group's internal combustion engines (MHEV and PHEV). Each of these plants is scheduled to produce 600,000 EDCT boxes a year, for a total of 1.2 million units a year..

These gearboxes are compatible with 1.2L and 1.6L engines, and it is reasonable to assume that production of 1.2L and 1.6L engines will be aligned with this target of 1.2 million units per year to meet demand.

AdvertisingTermoli: a plant in transition

The Termoli plant in Italy, another strategic production center, currently produces GME, GSE/Firefly and V6 engines. However, by 2025, this plant will be transformed into a battery gigafactory, in partnership with ACC. In the meantime, the project to switch to electric power is falling behind schedule[4].

It's perfect timing, the plant will continue to produce GSE/Firefly engines for the Fiat Panda Hybrid and the future Fiat 500 Hybrid. It is estimated that the production target for Termoli will be 200,000 hybrid engines per year until 2030, to cover the needs of these two iconic models.

100,000 since this covers sales of the Panda in Italy, and 100,000 for the 500 hybrid because is the volume target[5] which has been communicated by the Italian brand. This will allow time for a smooth transition to the battery gigafactory project over the coming years.

As for the GME engine, it no longer seems to have a future in European models and will be reserved for the North American market. As for the V6 engine, everything will depend on Maserati's decisions. If Maserati decides to go for the 100 % electric, production will be marginal and reserved for niche cars such as the MCXtrema, the 33 Stradale, and so on.

Emotors in Tremery: the production center for European electric motors

The Emotors plant at Tremery is dedicated to the production of electric motors for vehicles based on the STLA Smart, STLA Small and STLA Medium platforms. According to our informationThe plant aims to produce around 280,000 M2 engines a year, 40,000 M2 Erad engines (for models such as the Jeep Avenger 4xe and Alfa Romeo Junior Q4[6]) and around 600,000 M3 and M4 engines.

This represents a total production of nearly 900,000 electric motors every year. This plant is an essential link in Stellantis' transition to electric motors, with ambitious targets that should boost the share of electric motors in the Group's overall production.

AdvertisingEngine production in line with car sales

In total, this means producing around 1.2 million internal combustion engines and 900,000 electric motors per year (not counting the electric motors to be produced in Hungary in 2026). It should be noted that these motor production targets are largely dependent on actual market sales.

In 2024, Stellantis plans to produce around 500,000 vehicles in Italy, 600,000 in France and 350,000 in Spain.

The Group's other plants in Poland, Serbia, Slovakia and the UK will also play an important role in achieving these production targets.

| Hungary Szentgotthard | 1.2L | *1 000 000 |

| Hungary Szentgotthard | 1.6L | 220 000 |

| Hungary Szentgotthard | EDM 800V | unknown |

| Mirafiori | eDCT | 600 000 |

| Metz | eDCT | 600 000 |

| Tremery | emotors M2 | 280 000 |

| Tremery | emotors M2 erad | 40 000 |

| Tremery | emotors M3/M4 | 600 000 |

| Termoli | GSE/Firefly | *200 000 |

*estimates

AdvertisingReferences

- ^ Stellantis (www.italpassion.fr)

- ^ dossier on Stellantis electric motors (www.italpassion.fr)

- ^ production target for the 1.6L PHEV engine (www.italpassion.fr)

- ^ the project to switch to electric power is falling behind schedule (www.italpassion.fr)

- ^ is the volume target (www.italpassion.fr)

- ^ Alfa Romeo Junior Q4 (www.italpassion.fr)