Paris Air Show 2025: MTU Aero completes design of 600kW Flying Fuel Cell

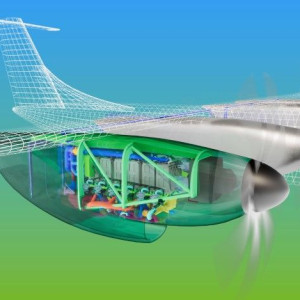

MTU Aero Engines has completed the design of its Flying Fuel Cell and has begun manufacturing fuel cell stacks for the demonstrator at its Munich facility in Germany. The company has reached several development milestones including finalizing the design, starting stack production, successfully testing the eMoSys electric motor, and commissioning the first test cell. The 600-kilowatt electric powertrain is aimed at regional aircraft applications.

"With the successful critical design review for our first electric 600-kilowatt powertrain, we are wrapping up the design phase and starting on manufacturing and assembly," said Barnaby Law, Flying Fuel Cell head engineer at MTU Aero Engines. Production of fuel cell stacks has begun at MTU's Munich facility. MTU is developing the electric motor for the Flying Fuel Cell powertrain with its subsidiary eMoSys in Starnberg, Germany.

In testing, the 600-kilowatt motor achieved maximum continuous output for the first time with efficiency rates exceeding 96% during both takeoff and cruising conditions. The company has built Flying Fuel Cell testing infrastructure at its Munich facility consisting of two test cells with hydrogen infrastructure, cooling water and pressurized air supply. The fuel cell stack test cell is operational and designed for stacks with up to 500 kilowatts of electrical power per unit.

A second testing setup, the system test cell, is under construction and will be used to test the entire engine system. According to MTU, the testing infrastructure supports development of the complete powertrain system. The Flying Fuel Cell serves as the foundation for the HEROPS clean aviation research project.

The Hydrogen-Electric Zero Emission Propulsion System program involves seven partners led by MTU developing technologies for climate-neutral, hydrogen-driven electric powertrains for regional aircraft starting in 2035. The HEROPS project, which began last September, plans to build a ground fuel cell powertrain demonstrator with 1.2 megawatts of power during its three-year period. According to MTU, the partners aim to prove feasibility of the technologies and demonstrate scalability reaching between two and four megawatts using modular engine architecture.

HEROPS industry partners include MT Aerospace, Collins Aerospace, Lufthansa Technik and Eaton. Research partners are Royal Netherlands Aerospace Centre and Technical University Vienna. The partners will first analyze powertrains with outputs of up to 1.8 megawatts before building the HEROPS ground demonstrator.

According to MTU, the project will prove that the technologies are feasible and can be scaled to outputs between two and four megawatts using modular engine architecture.