Mavel Powertrain chooses Syensqo materials to boost EV motor efficiency and thermal performance

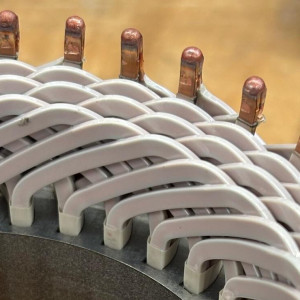

Syensqo has announced that its innovative Ajedium PEEK (polyetheretherketone) slot liners and slot wedges and KetaSpire PEEK magnet wire insulation have been selected by Mavel Powertrain[1] for integration into their latest high-voltage electric motor for a renowned premium sports car manufacturer. "We are excited to collaborate with Syensqo[2] and integrate their advanced Ajedium and KetaSpire PEEK solutions into our latest high-voltage electric motor," said Luca Favre, head of motor development at Mavel Powertrain. "Material excellence is at the core of our commitment to delivering cutting-edge electric powertrains to our automotive customers." The combination of Ajedium PEEK slot liners and monolayer KetaSpire PEEK magnet wire aims to enhance electric motor efficiency, supporting operations at over 800V.

The materials' reduced thickness allows for more copper in the motor design, improving electrical output and thermal management.

"We are proud to partner with Mavel on a project that demonstrates the tangible improvements in efficiency that our solutions bring to electric vehicles," said Brian Baleno, director of global business development and program management at Syensqo. "This development is an important stride toward increasing the viability and capabilities of battery-electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs) and hybrids."

In related news, Monumo has used its machine learning Anser engine to achieve an 11.4% reduction in the bill of materials (BOM) for an EV powertrain, including a 23% reduction in magnet volume. Monumo says these advances could save OEMs up to EUR50m (US£57m) for every million motors produced[3]

References

- ^ Mavel Powertrain (www.mavelpowertrain.com)

- ^ Syensqo (www.syensqo.com)

- ^ Monumo has used its machine learning Anser engine to achieve an 11.4% reduction in the bill of materials (BOM) for an EV powertrain, including a 23% reduction in magnet volume. Monumo says these advances could save OEMs up to EUR50m (US£57m) for every million motors produced (www.automotivepowertraintechnologyinternational.com)