France unveils the “impossible engine” to the world: It’s the first to work without this material

In July of 2022, French global automotive supplier Valeo closed on a deal with German multinational technology conglomerate Siemens. Siemens gave up its share of a joint venture partnership between the two powerhouses and took home a profit of 300 million euros. The two industrial giants were developing the Valeo Siemens eAutomotive (VSeA) to develop electric mobility solutions. Now, Valeo is pursuing projects with Renault Group.

Valeo intended to accelerate development of electrical mobility solutions

Valeo's full ownership of the VSeA project came with their ambition to increase and accelerate the technological advancement and output of electrical mobility solutions.

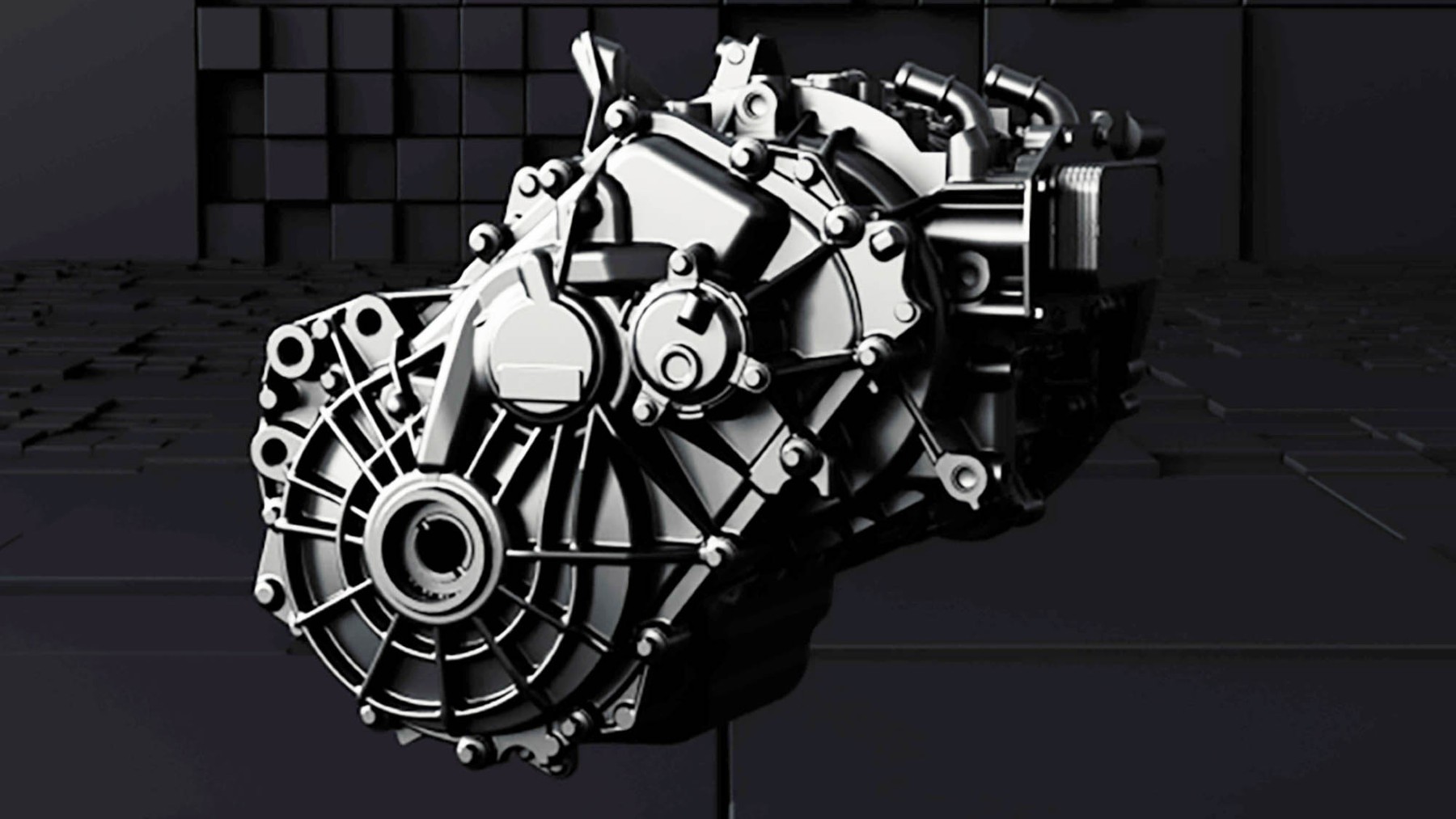

In 2023, Valeo and Renault Group to develop the E7A prototype motor which is set to debut in 2027. The motor is powerful, efficient, and most importantly uses no rare earth materials which would be the first of its kind. At the time of Valeo's full acquisition of VSeA, they estimated they would achieve a growth output of 15% by 2025.

At the time of the splitting of Valeo and Siemens, Valeo had announced its partnership with Renault to design, co-develop, and produce a one-of-a-kind type of electric motor. With the unveiling of the E7A a year ago, it seems that the new partnership achieved exactly that.

A new electric motor generation is set to take over the world

The joint partnership intends to develop a third generation set of motors for Renault. Renault was the first to introduce electrically excited synchronous motors (EESMs) in production vehicle back in 2012.

This previous development has meant that the E7A is in a strong place all-in-one architecture. This would make it 30% more compact for equivalent power than the current motors equipping the Megane E-Tech electric and the Scenic E-Tech electric. The rare-earths-free rotor technology would reduce the motor's carbon footprint by 30%.

A more powerful and efficient motor system

Renault has replaced permanent magnets in the motor with a wound rotor to improve its output.

This also means that the reliance on earth metals is no longer needed. The system will be built with voltage capacity of 800 volts instead of 400 volts as is standard for today. The motor will unleash up to 200kW. Further, the motor will using use cornerstone Valeo hairpin technology to assemble copper wires.

Renault has been in charge of the design and production of the rotor while stator has been designed by Valeo and Valeo eAutomotive. Renault is currently committing to phase out newly developed combustion-powered cars by 2035 in align with EU carbon-neutral commitment. Renault's carbon-neutral plan is to reduce green house gas emissions during vehicle production phase, also upstream, from design and procurement of parts and materials, and downstream when vehicles are on the road.

Renault plans on using materials in the vehicle design stage which emit fewer green house gases including through the use of recycled materials. Renault currently has a target goal of using 33% recycled materials by 2030. Currently, Renault is already spearheading with this project with the Scenic E-Tech Electric which is made from 24% circular-economy materials.

Renaults main focus will be on the use-stage of vehicle production. The usage part of production represents the biggest perpetrator of the carbon footprint for automobiles. It is therefore critical that this part of the car's lifecycle has the most attention paid to it.

Renault's current solution to this is by focusing on their electrical vehicle range. The current trajectory for Renault is to achieve carbon-neutrality by 2040 in Europe and 2050 for the rest of the world. In the last twenty years, they have already reduced their carbon footprint by 28%.

The company is confident that they will achieve their goals by the anticipated 2050 timeline.