Engine-driven vs. electric chillers: which is best for your cooling needs?

When it comes to selecting between engine-driven chillers and electric chillers, the decision isn't always straightforward. Both play essential roles in cooling systems for commercial buildings, industrial facilities, and controlled agricultural environments, but they vary widely in terms of efficiency, operational costs, and environmental impact. So, how do you determine which chiller is the best fit for your needs?

"Understanding these distinctions is key to making the right decision. There are trade-offs, and the choice really depends on the specific needs of your operation,"says Dalton Allaben, Sales engineer at Tecogen Inc. In any greenhouse or indoor farm, effective cooling is vital.

A chiller, whether located outside using ambient air or inside a mechanical room with a cooling tower, circulates chilled water around the canopy. As Dalton explains, "For larger climate-controlled spaces, a chilled water plant is the most efficient way to transfer heat and can easily be paired with hot water for dehumidification." This setup optimizes the growing environment, ensuring crops thrive in the best possible conditions.

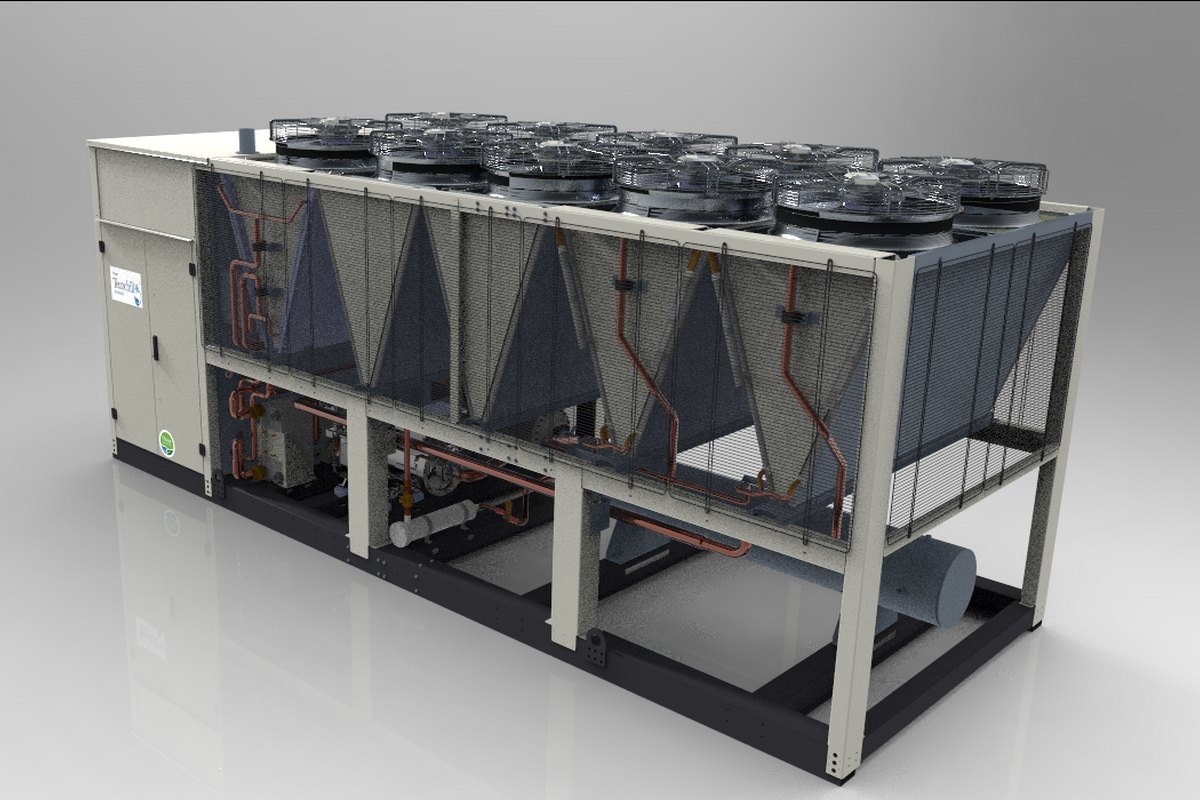

Tecogen's hybrid-air cooled chiller

Engine-driven vs. electric chillers

Dalton elaborates on the fundamental differences between engine-driven and electric chillers. Engine-driven chillers use a mechanical engine fueled by natural gas to power the compressor. "The key advantage here is versatility," Dalton says. "Engine-driven chillers provide both cooling and heating through combined heat and power (CHP) systems, repurposing waste heat for added efficiency." In contrast, electric chillers run on electric motors and rely on grid electricity.

While quieter and with fewer moving parts, Dalton points out, "Electric chillers are simpler but lack the added functionality of heat recovery, which limits them to cooling only." This makes electric chillers a more straightforward solution but one that doesn't offer the same level of efficiency in complex environments. Efficiency is 'not as simple as it seems'

When comparing efficiency, electric chillers are often seen as more efficient, but Dalton highlights the complexity. "Electric chillers generally have a higher Coefficient of Performance (COP) at the point of use," he says, "but you have to account for inefficiencies in the generation and transmission of electricity." Engine-driven chillers, on the other hand, use a "source" COP that factors in their ability to produce and use energy on-site. Dalton provides an example: "An electric chiller might have a site COP between 3 and 6.5, but once you factor in power generation and transmission losses, that figure can drop significantly." Engine-driven chillers, by contrast, maintain more consistent efficiency and are often a more cost-effective solution in areas where electricity rates are high.

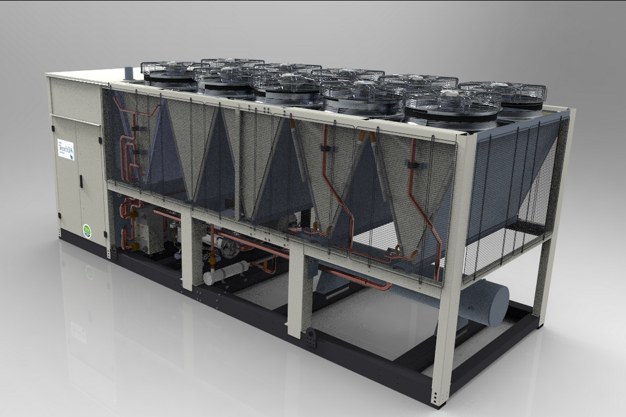

The water-cooled engine-driven chiller Maintenance and environment

A common concern about engine-driven chillers is their maintenance needs, but Dalton offers some reassurance. "It's true that engine-driven chillers require more maintenance," he says, "but the difference is smaller than people think. You're looking at about 16 hours of preventive maintenance annually for engine-driven chillers, compared to 8 hours for electric chillers."

With engine-driven chillers boasting uptime rates of over 99.8%, Dalton emphasizes that "the additional maintenance is manageable and doesn't pose a major operational burden, especially when you consider the reliability they offer." While electric chillers are typically considered more environmentally friendly, Dalton stresses the importance of looking at the bigger picture. "Electric chillers draw from the grid, which includes renewable sources, but during peak demand, it's natural gas power plants that are providing additional capacity," he notes. These plants operate inefficiently and suffer from transmission losses, which can offset the environmental benefits.

"Engine-driven chillers, by contrast, operate like localized power plants," Dalton says. "They use energy directly and capture waste heat for additional use, achieving overall system efficiencies of up to 85%. This makes them a compelling option for facilities looking to lower their carbon footprint." When to choose engine-driven chillers

In Dalton's view, engine-driven chillers are ideal in specific situations. "They're best for facilities where electricity costs are over £0.07/kWh, natural gas is available, or combined heat and power (CHP) systems can be used," he explains.

Engine-driven chillers are also a great choice for locations with unreliable electrical infrastructure or areas prone to severe weather, as they provide built-in resiliency by operating independently of the grid. In the end, Dalton concludes, "Choosing between engine-driven and electric chillers comes down to your specific operational needs and goals. There's no one-size-fits-all solution, but understanding the options can help you make the best choice."

For more information:

For more information:

Tecogen

Dalton Allaben, Sales engineer

[email protected]

www.tecogen.com[1][2]

References

- ^ [email protected] (www.hortidaily.com)

- ^ www.tecogen.com (www.tecogen.com)