Canada unveils engine that beats hydrogen: Bad news for America and an unexpected fuel

Canada has taken a historic step in joining the mobility of the future, moving beyond EVs (in which America has been somewhat stagnant) and entering into direct competition with Japan. CES 2024 happened months ago, but we are still learning about innovations that were presented and have jumped to fame. One of them is the first engine that beats hydrogen and all known FCEVs.

It works with a new fuel that is neither liquid nor gaseous, and could make things very difficult for Tesla.

It's the end of ICE engines: A new prototype has been presented at CES 2024 and comes from Canada

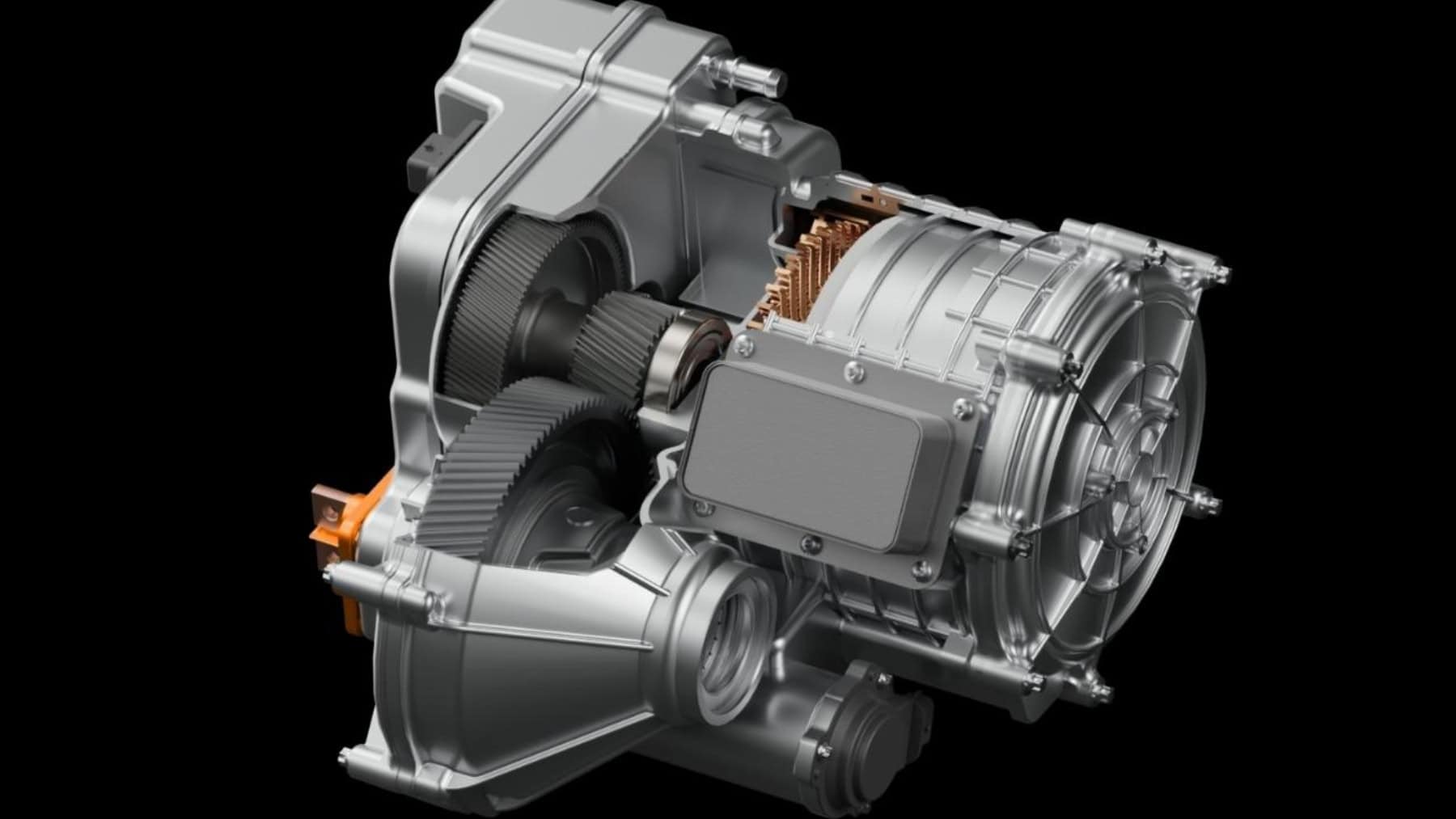

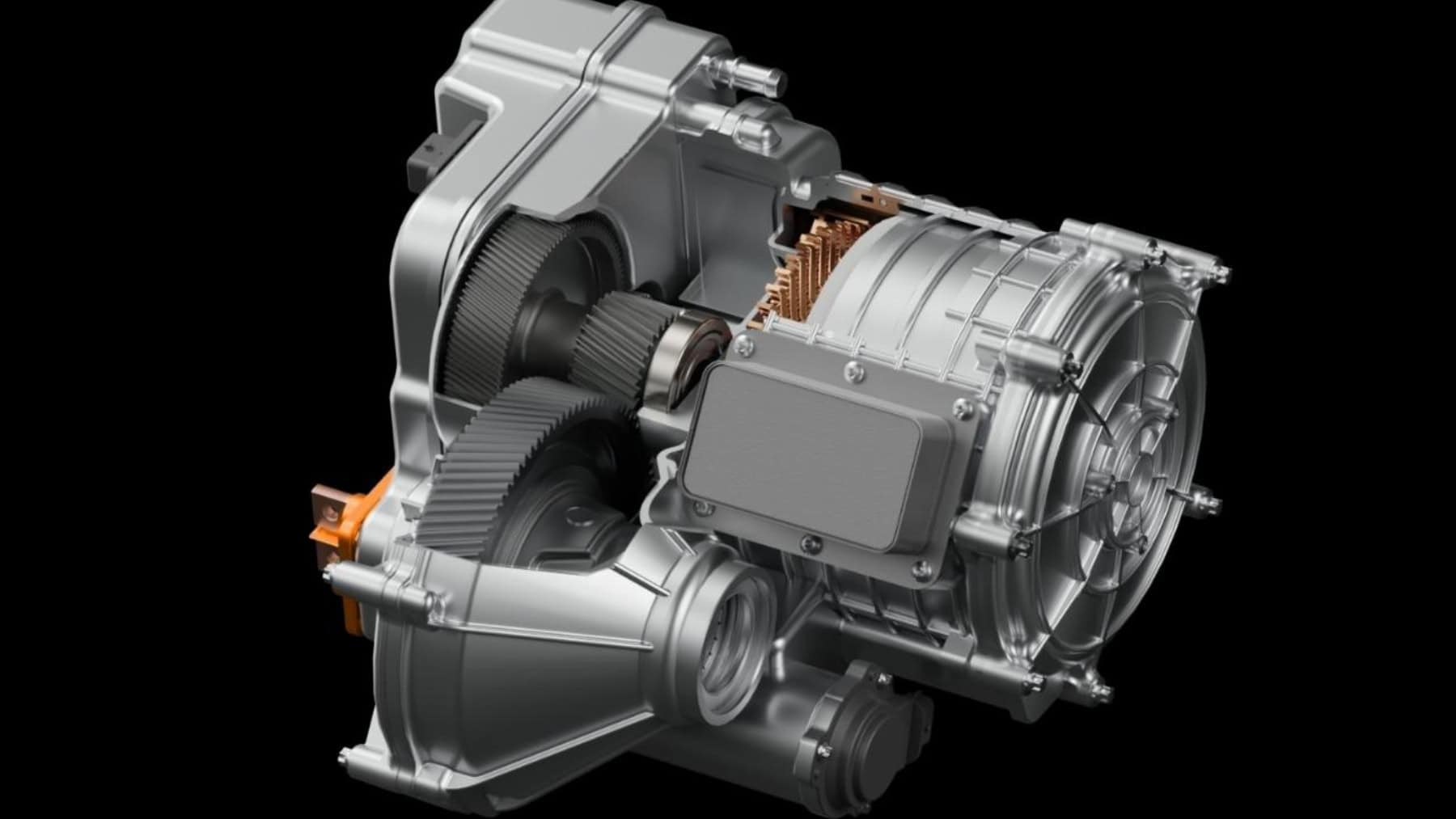

Magna has revealed the next generation of its eDrive system at the CES 2024 with a demonstration of its capabilities for advanced electric vehicles. This new electric engine is still experimental, but it is expected to change the way most cars are designed and used in the future because it has better performance and adaptability to other uses than previous models. This new electric engine by Magna is, therefore, developed to produce immense performance and efficiency, making it a reference in the EV market.

The engine is highly compact and light in weight, which makes it fit for different types of cars, right from the small cars to SUVs and commercial transports. It is also worth mentioning that the principal feature of Magna's eDrive is modularity, which provides applicants with a preview of how this system can be smoothly incorporated into different platforms. This flexibility helps the automakers be ready for market requirements and the customer needs much faster, paving the way for the EV segment in the automotive environment at a faster pace.

New generation of electric engines will open the doors to "future EVs": Up to 469 hp, and this unprecedented detail

The next generation of the eDrive as seen in Magna neatly encapsulates performance figures that appear to match the traditional ICEs.

The engine has the prospective to deliver maximum power of up to 350 kW (469 hp) and a torque of up to 730 Nm to enable electric vehicle users to have a thrilling ride. Speaking of efficiency, Magna's eDrive system allows reaching a power density within the class of up to 50 kW/L in an improved range, as well as minimizing energy consumption. The efficiency of the new engine is outstanding due to the improved cooling system and geometry of the design; hence, the new invention will attract car manufacturers looking forward to enhancing the performance.

The Innovation case for the development of Magna's Next Generation eDrive System is characterized by steady innovation and strategic partnerships with partners. The company has also engaged in research and development to come up with an elite electric engine solution that the car manufacturing company possesses the knowledge of engineering automobiles.

Are there plans for a large-scale commercialization? Magna has unveiled what to do with its new electric engine

Another area in which Magna has successfully implemented particular craftsmanship in its eDrive is the employment of new materials and technology.

Lightweight and high-strength materials like aluminum and advanced composites are employed right from the roughed-out engine parts and sub-assemblies. Also, manufacturing practices of eDrive systems at Magna have been improved and standardized to produce reliable systems of high quality. Looking at the growing market for electric vehicles, the next-generation eDrive system from Magna is expected to be one of the major spokes in the wheel of progress.

The Company has already signed some deals with major car manufacturers, who are willing to incorporate Magna's eDrive technology into future production electric cars. The possibility to change, in different degrees, the paths that have been mapped up to this point might be the key to future success and, in this sense, the commitment that Magna has declared to innovation. The new Magna electric engine opens the door to a completely different generation of EVs, characterized by standardizing extended range and pushing efficiency to the maximum.

The key, according to experts, will be to minimize wear and tear with innovative materials, such as the nickel-aluminum we saw some time ago or even titanium.

It remains to be seen whether Canada succeeds in this challenge or whether it ends up as an experimental prototype, although the former is more likely to be the case.