Additive Drives and Daikin Chemicals to Create New 3D-Printed Electric Motor Materials

Additive Drives[1] and Daikin Chemicals[2] are taking a leap forward in electric motor innovation[3]. The German-based Additive Drives and Daikin Chemicals, a Japanese company with a European subsidiary, have expanded their collaboration to create high-performance materials with better insulation and enhanced efficiency. These materials promise to boost the durability and performance of electric motors, even under extreme heat and exposure to various chemicals that could degrade their components.

For example, electric motors used in high-performance cars face high heat and exposure to various fuels and lubricants. At the same time, motors used in industrial applications and chemical processing plants also face harsh environments, operating amid reactive and corrosive chemicals. This joint project aims to create materials that improve how electric motors work and last longer.

The new materials being developed have thin layer thicknesses and insulation capabilities that prevent partial discharges, a common issue that can degrade motor performance over time. These materials also have excellent dielectric properties, meaning they can store and manage electrical energy efficiently without conducting electricity, making them ideal for tough conditions where electric motors are used. One of the standout features of these new materials is their ability to boost the overall efficiency of electric motors.

According to Additive Drives, tests have shown that motors using these materials have improved insulation properties and higher efficiency compared to similar motors made with conventional materials. This improvement in efficiency is not only a technical success but also helps make energy use more sustainable, supporting global efforts to fight climate change. Axel Helm[4], CEO and co-founder of Additive Drives, stated, "Additive Drives is pursuing the goal to make electrification simpler, better and more sustainable.

The joint development is a great step towards taking electric drives to a new level all over the world." Additive Drives is not just focused on material development; the brand helps its partners through every step of making electric motors. This includes designing, building, testing, and getting the motors ready for production.

By offering complete support, Additive Drives says it ensures that its innovative designs and top-quality insulation methods turn into efficient and sustainable finished products.

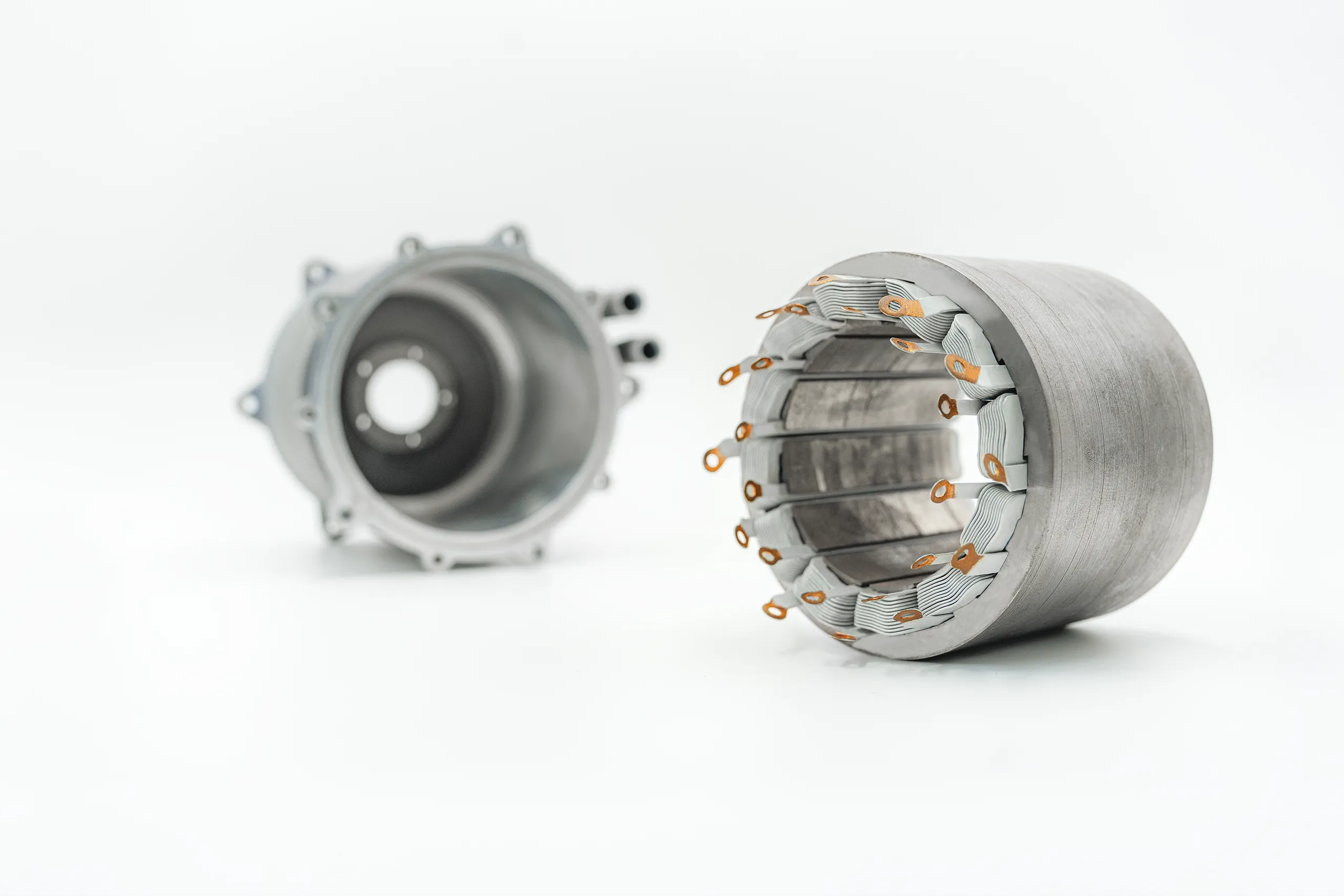

Single coil motor. Image courtesy of Additive Drives. A key factor in Additive Drives' capacity to innovate is its use of 3D printing technologies.

The company relies on Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) to produce copper windings for electric motors. These 3D printing technologies allow for the creation of complex geometries that are not possible with traditional manufacturing methods, resulting in motors that are lighter, more efficient, and have up to 45% improved performance. This capability is also crucial for developing new high-performance materials in collaboration with Daikin Chemicals.

Additive Drives and Daikin Chemicals have committed to a long-term partnership to develop energy-efficient electric motors. Over the coming years, this collaboration aims to contribute to global climate protection by creating motors that are both more efficient and sustainable. Philipp Arnold, Additive Drives' Chief Financial Officer (CFO), highlighted the importance of this collaboration, saying, "With oil cooling, high-speed applications, and rising requirements regarding Partial Discharge Inception Voltage (PDIV), there is a strong need for high-performance insulation material.

We are looking forward to pushing these boundaries together with Daikin Chemical Europe." With strong backing from industry and academic partners like the Freiberg University of Mining and Technology (TU Bergakademie Freiberg[5]) and the German startup network SAXEED[6], which supports entrepreneurial activities and innovation, Additive Drives' electric motor development gets a significant boost. An EXIST research transfer project at TU Bergakademie, which provides substantial financial aid and resources to help high-tech startups commercialize their technologies, further supports their efforts in advancing technology and scaling production.

This combination of academic, industry, and financial support has helped Additive Drives grow and establish collaborations with prominent clients such as Porsche[7], Airbus[8], Mercedes[9], Bosch[10], and BMW[11], reflecting their impact across the automotive, aviation, and robotics industries.

Additive Drives develops 3D printed electric motors. Image courtesy of Additive Drives. Recently, Additive Drives secured a £1.5 million seed investment[12] from AM Ventures[13], which is being used to advance its market launch and scale up operations in both prototyping and high-performance series applications.

This funding is expected to help the company reduce the development time for electric motors by half and expand its technological leadership in the industry. Additionally, Additive Drives is part of a new consortium aiming to develop advanced additive manufacturing processes for electric motors. This consortium includes major industry players such as Ford[14] and Thyssenkrupp[15] and focuses on innovating new production techniques for next-generation electric motors.

The joint development agreement between Additive Drives and Daikin Chemicals marks a new milestone for the German startup. By leveraging high-performance materials with dielectric properties and utilizing cutting-edge 3D printing techniques, this collaboration aims to set new standards for efficiency and sustainability in the electric motor industry. As this partnership progresses, it holds the potential to impact global efforts to create a more sustainable and electrified future.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Please enable JavaScript to view the

comments powered by Disqus.[16]References

- ^ Additive Drives (www.additive-drives.de)

- ^ Daikin Chemicals (www.daikinchemicals.com)

- ^ electric motor innovation (3dprint.com)

- ^ Axel Helm (3dprint.com)

- ^ TU Bergakademie Freiberg (tu-freiberg.de)

- ^ SAXEED (www.saxeed.net)

- ^ Porsche (www.porsche.com)

- ^ Airbus (www.airbus.com)

- ^ Mercedes (www.mercedes-benz.com)

- ^ Bosch (www.bosch.com)

- ^ BMW (www.bmwgroup.com)

- ^ £1.5 million seed investment (3dprint.com)

- ^ AM Ventures (amventures.com)

- ^ Ford (www.ford.com)

- ^ Thyssenkrupp (www.thyssenkrupp.com)

- ^ comments powered by Disqus. (disqus.com)