MFV ‘ZENITH’ | Macduff Ship Design Ltd

The vessel was built by Macduff Shipyards for owner Mark Robertson, along with sons Paul and Adam. This fishing vessel replaces the owner’s previous two fishing vessels, ZEYPHR BF 601 (ex UBEROUS) built by the yard in 2005 and ZENITH BF 106 (ex DAYSTAR) built by the yard in 2008. The vessel is intended to fish out of Fraserburgh in the North East of Scotland, targeting primarily prawns in the North Sea region.

ZENITH is the second vessel in a series of three sister ships, all of which are being built at the yards newly developed Buckie site. The vessel follows on from the CELESTIAL DAWN BF 109 which was handed over in the summer of 2022, and will itself be followed by the third sister ship FOREVER FAITHFUL, now well under construction. All three vessels feature the same hull form and general fishing arrangement; however, each have their own unique internal layout to suit the owners’ preferences.

Show Fullscreen

Designed between the yard and Macduff Ship Design, during the early design phase of the lead vessel the yard commissioned the Wolfson Unit in Southampton to run a case study of two hull forms utilising CFD technology. The first hull form was a design previously built by the yard for a similar type of fishing. The second was the new concept model featuring increased length, a gradual bustle forward of the propeller and a unique stem where the bulbous bow was not fully submerged but rather tapered gradually into the bow’s upper region. Results from the study indicated a significant reduction in hull resistance at the two test speeds of 8 and 10 knots which has now been verified during the first year of service of the sister ship. Another significant difference between designs were an increase in beam from around 7.0 m of earlier vessels in this category up to around 7.6 m. The increase in beam allowed the vessel to carry less internal ballast whilst also creating more deck space which was of particular benefit within the accommodation and fish processing areas. This increase in hull efficiency enables the owner to save fuel, and in turn, reduce the emissions and environmental impact of the vessel.

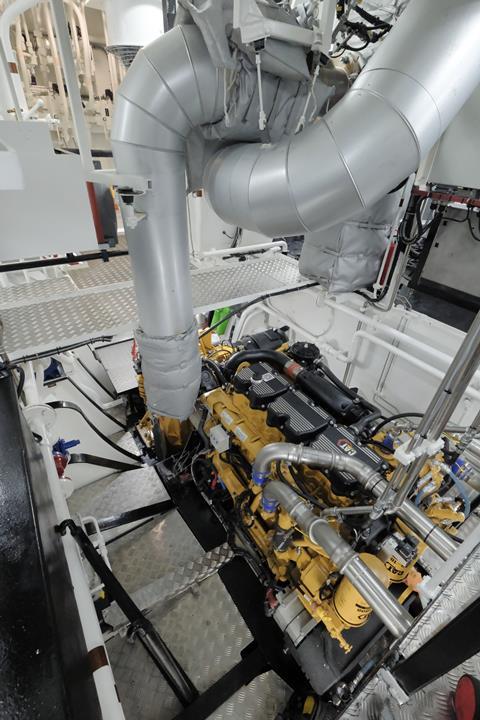

To further reduce the environmental impact of the ZENITH, the propulsion package was very carefully considered. The vessel features a Novga (previously Heimdal) CPP stern gear package with a 2.3 m diameter controllable pitch propeller, housed within a nozzle, coupled to a large reduction gearbox complete with two PTOs for hydraulic power, driven by a Caterpillar C18 main engine with power output of 600 hp. With one engine driving both propulsion and hydraulics, the engine is kept with an efficient operating window with no significant periods of idling and energy loss.

Show Fullscreen

The C18 main engine on ZENITH was one of the first pair of IMO Tier III certified engines to be fitted by the yard. A SCR and urea/AdBlue system is fitted in the engine room, provided by Xeamos of the Netherlands, which allows the engine to meet the new, more stringent emission standards set by the IMO. Certification of the engine and SCR system was arranged by Finning CAT who assembled the complete system on their test bed in Cannock, with witnessing and certification provided by DNV/GL. The system was proven to work well during sea trials where the 35 dB reduction SCR silencer helped the reduce noise levels throughout the vessel.

The hull of ZENITH is built entirely from steel, apart from the wheelhouse and mast which are aluminium, and features a double chine hull form, transom stern and modern bow designed to cut cleanly through the sea with less energy leading to a reduction in fuel consumption and emissions along with increased crew comfort. In broad terms the layout of the ZENITH is like some of the other recent new builds produced by the yard. Below deck features the cabins, engine room, fish hold and a large freshwater tank forward of the collision bulkhead. Whereas above deck is situated the aft shelter, galley/mess and side passage area, fish processing area winch room.

Particular attention was paid by the owner to the arrangement of the accommodation and fish processing areas onboard. The galley is of considerable size with comfortable living space for the live on-board crew, as is the washrooms, laundry and dry locker spaces. The fishing processing area has been optimised and uses the available space neatly. Care and attention were also placed on positioning of equipment to maximise efficiency to reduce the crews workload. It features conveyor belt to sort the catch in place of a traditional tray which lifts the product out of the hopper and six different prawn washers within arm’s reach of the sorting belt. A flush hold unloading hatch is also fitted in the fish processing area forward which creates a larger floor space which is a benefit at sea when the hatch is not used anyway.

Show Fullscreen

A bespoke hydraulic deck machinery package was fabricated by the yard including of a triple barrel winch featuring a Hagglunds compact CA210 motor, two split net drums complete with two Hagglunds compact CA100 motors per drum, two general purpose gantry winches and a cod end lifting winch. Thistle Marine of Peterhead supplied both the MFB8 landing crane and MBK7 power block crane, both of which featuring a slew ring base. A small hoisting winch is fitted to help the move the catch in the hold when landing.

Primary hydraulic power is provided by two pumps driven from the gearbox PTOS. At the owners request a unique secondary hydraulic system was fitted which features two electric motor driven pump sets, one of 75 kW and the other of 45 kW duty. These two pump sets allow the hydraulics to run very close to full power and speed, providing not only a net retrieve system but full redundancy.

Cooling systems for all engines and hydraulics onboard are served by box coolers supplied by Blokland Non-Ferro.

Electrical power onboard is provided by two Mitsubishi generator sets supplied by Macduff Diesels Limited, each with a rating of 98 kWe and of sufficient size to run the vessels power independently providing complete redundancy.

The electrical systems onboard were designed and fitted by R.D. Downie who also fabricated the vessels switchboard and control panels for all the pumps and motor starters. In addition to this R.D. Downie also provided the fire, bilge and gas alarm systems onboard along with the navigation light panel and assisted with the installation of the navigation equipment.

Show Fullscreen

The fish processing deck features a catch handling system built by the yard and Northeast Fabricators. A separate compartment is formed within the fish processing area which house both the ice plant room as well as an access hatch and fixed permanent stair to the hold. The fish hold refrigeration system along with ice machine was supplied and fitted by Premier Refrigeration.

The vessel was fully painted by the yard with International products applied to a comprehensive marine spec.

The high specification navigation package was supplied and fitted onboard by Woodsons of Aberdeen.

GENERAL PARTICULARS Length overall: 22.75 m Length Registered: 21.83 m Beam: 7.60 m Depth: 4.15 m Gross Tonnage: 222 t Depart port displacement: 310 t Fresh water capacity: 15500 li Oil fuel capacity: 21000 li Hold capacity: 600 boxes Speed: 10.0 knots Crew: 6-8LIST OF MAJOR SUPPLIERS Construction drawings and stability information supplied by Macduff Ship DesignCaterpillar C18 main engine supplied by Finning Power Systems, UKNozzle supplied by Kort Propulsion, UKPropeller and Gearbox supplied by Novga, NorwayGenerator sets supplied by Macduff Diesels Ltd, UKBox cooling systems for each engine and the hydraulic circuit supplied by Blokland Non Ferro, NetherlandsPumps supplied by Azcue Pumps SA, SpainDeck machinery equipment supplied by the yardDeck cranes supplied by Thistle Marine, UKFire doors supplied by B-15 Marine Ltd, UKWeathertight doors supplied by Winel, NetherlandsRudder system supplied by the yardSteering gear supplied by Scan Steering APS, DenmarkWheelhouse windows and portlights supplied by HK Van Wingerden & An BV, NetherlandsFish handling system supplied by the North East Fabricators, UKRefrigeration system and ice machine supplied by Premier Refrigeration, UKPaint system by International, UKWheelhouse chairs supplied by Norsap, UKOil fuel filter/separator and main engine oil fine filter supplied by CC Jensen, UKPressure washers supplied by Grampian Power Clean, UKAnchors and chain supplied by Fendercare Marine, UKSwitchboard and electrical system supplied and installed by R D Downie Limited, UK

For more information contact: Macduff Ship Design[1]+44 (0)1261 833 825 | [email protected]

References

- ^ Macduff Ship Design (www.macduffshipdesign.com)